Warm water underfloor heating

Water underfloor heating, also known as wet underfloor heating, is an extremely efficient and effective method of heating, suitable for a wide range of projects. The system uses a series of pipes connected to your heating source via a manifold, which then circulate warm water throughout the floor to heat the space. The heat emitted is more evenly distributed than a single radiator, which means the system can use water at a lower temperature.

Your water underfloor heating system can be linked to almost any heating source, from a traditional boiler to renewable technologies such as heat pumps or solar thermal.

Underfloor heating is often associated with tile, stone or wooden flooring. Whilst these are some of the most popular floor types to be used, underfloor heating is actually really versatile and can be used underneath a wide range of floor types.

Our products

Screed system

Underfloor heating pipes are installed on insulation, with staples used to fix the pipes, prior to the screed being laid.

Features and Benefits

- Most popular way to install underfloor heating

- Flexible installation

- High heat output for any given temperature

- Simple to install

- Can be used with traditional or liquid screed

Beam and Block system

Similar to screed on insulation, underfloor heating pipes are installed and secured with clips.

Features and Benefits

- Flexible installation

- High heat output for any given temperature

- Simple to install

- Can be used with traditional or liquid screed

Overboard Retro-Fit Gypsum Boards

A dry screed panel is used to lay over an existing floor, a 12mm pipe is then inserted within the groove which gives you the high output required. Virtually any floor covering can then be laid on top.

Features and Benefits

- Flexible installation

- Dry assembly

- No need for excavation

- Low profile (18mm boards)

Profoil EPS Grooved Insulation Boards

Profoil is a grooved EPS insulation panel with a bonded aluminium reflecting layer. They can be used in a variety of ways, whether over screed or timber and are used with a standard 16mm underfloor heating pipe, installed within the grooved panels.

Features and Benefits

- Flexible installation

- Lightweight

- Simple to install using a single panel for straight runs and returns

- Minimal increase in floor height

Profix panels with Self Levelling Compound

A castellated panel is laid across the floor and a 12mm pipe is then inserted within. A self levelling compound is then poured across the install giving an increase in floor height of as little as 14mm. A 6mm or 10mm XPS insulation layer can be bonded to the underside if required.

Features and Benefits

- Flexible installation

- No need for excavation

- Increase in floor height as little as 14mm

Dry mix battened system

An 8:1 sand and cement mix is used to cover the pipes which acts as a thermal mass.

Features and Benefits

- Simple to install

- Flexible installation

- High heat output for any given temperature

- No wet screed is required so no drying time

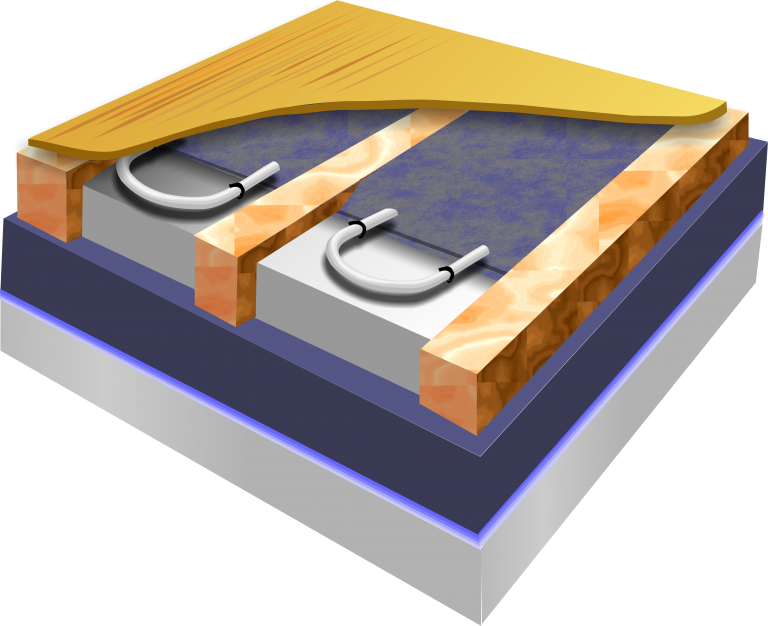

Between Joist with Aluminium plates

Pre formed aluminium plates are suspended between the joists, the pipes are then installed within the grooves, providing a quick and lightweight easy installation.

Features and Benefits

- Flexible installation

- Simple to install

- Reduction in weight compared to dry mix

- No increase in floor height

- No wet screed is required so no drying time

Fit from below with Joist Aluminium Plates

Also using an aluminium plate, this system allows underfloor heating pipes to be fitted below existing floors.

Features and Benefits

- Flexible installation

- Simple to install

- Reduction in weight compared to dry mix

- No increase in floor height

- No wet screed is required so no drying time

Dry Mix Between Joist system

Underfloor heating pipes are fixed between the joists on an insulation layer, using an 8:1 sand and cement mix is then used to cover the pipes which acts as a thermal mass.

Features and Benefits

- Simple to install

- Flexible installation

- High heat output for any given temperature

- No wet screed so no drying time required

Dry Mix Over Joist system

An 8:1 mix of dry sand and cement is used as the thermal layer and helps transfer the heat from the pipe to the underside of the floor.

Features and Benefits

- Simple to install

- Flexible installation

- Minimal increase in floor height

- No wet screed so no drying time required